Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Tel:15662735099

Add:Shandong Zhangqiu Zaoyuan Economic Development Zone

The rotary feeder is an important component of various dust removal equipment's ash discharge technology, ensuring the sealing of the silo and the effectiveness of continuous or continuous ash discharge; The ash hopper of a high negative pressure electrostatic precipitator has a significant sealing effect when storing dust at a certain height. The rotary feeder is a very important component in pneumatic conveying equipment. It is widely used and can be used as a feeder in pressure feeding equipment, or installed under the separator or dust collector of suction feeding equipment as a unloader or ash unloader.

The scale and speed of the rotary feeder need to be determined based on the transport volume and the packing density of the material, and special attention should be paid to the condition of the material entering the feeder. Regarding materials that can be fluidized, when they are in an inflated state, their bulk density will be greatly reduced, so the volume of the feeder needs to be much larger to pass the same amount of material. In order to accurately determine the scale of the rotary feeder, it is necessary to grasp the packing density of the material's inflation condition. There are various types of rotary feeders available, and the layout of rotary feeders used for pneumatic transportation should be planned according to the heavy-duty operation level.

It is one of the important components in the pressure and suction pneumatic conveying system, which can uniformly and continuously feed the clinker pipe. In the separation and dust collection parts of the system, it also has the functions of an unloader and an air lock.

Rotary feeders are the main equipment for conveying bulk and powdered materials. They are widely used in industries such as grain processing, chemical raw materials, plastic metallurgy, energy mining, building materials and cement, docks, malt workshops in breweries, brewing workshops, etc. due to their high reliability and affordable price.

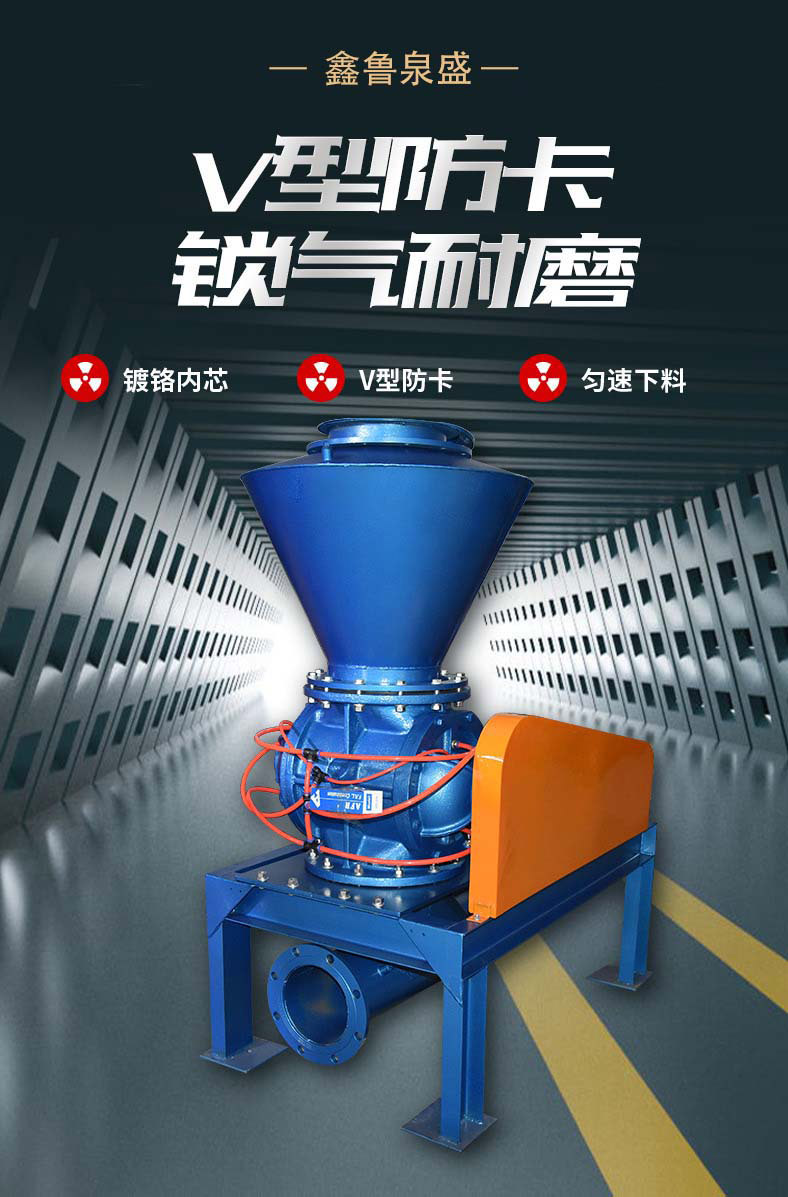

The main components of the rotary feeder are: main valve (housing, end cover, impeller), motor reducer, protective device (sprocket), suction chamber, acceleration chamber, anti jam feeder, etc.

Rotary feeders come in standard, wear-resistant, and measuring suspension types.

1. Standard type: Both the upper and lower flanges are circular. For special reasons required by users, such as square and rectangular flange connections, they can be determined separately. The flange thickness is specified according to the company's standards.

2 Wear resistant type: suitable for hard and abrasive powders, with replaceable inner lining inside the casing to improve service life and facilitate replacement.

3. Measurement suspension type: It is a specially designed model according to different installation requirements. Its main feature is that the deceleration motor is a measurement type, which is directly connected to the host through a connecting plate, saving the base and installation space. It is suitable for the bottom of the silo or structures without ground support

The shape of the rotor inside the rotary feeder includes P-type (linear type, suitable for powder materials) and V-shaped (herringbone type, which is one of the measures to effectively reduce material jamming between the rotor and the casing for conveying granular materials)

The function of the rotary feeder suction chamber: For materials with low packing density, especially powder materials, it is set up to ensure that the materials fall normally and that the gas is discharged without affecting normal transportation.

The function of the rotating feeder acceleration chamber: When the feeding port of the feeder supplies powder and granular materials to the conveying pipe, it accelerates the conveying without causing significant pressure loss.

Selection of Rotating Feeders

How to choose a rotary feeder? There are many factors to consider when selecting a rotary feeder. The selection of a rotary feeder generally depends on the calculation method of its conveying capacity, the specifications of the conveyed material, the installation method, whether it needs to be equipped with an acceleration chamber or an exhaust chamber, whether the inner cavity and blades need special treatment, and whether they are explosion-proof

Performance of conveyed materials: name, particle size, bulk density, temperature, angle of repose, moisture content

Rotating feeder conveying capacity: hourly conveying capacity T/H or m ³/h.

Calculation method for rotary feeder:

W(m³/H)=V(L/rev)xN(rpm)x60xη(%)/1000

W: Unloading volume (m ³/H)

V: Rotor volume (L/rev)

N: Rotor speed (rpm)

η: Volume efficiency of rotor (%)

Installation method of rotary feeder: front or side mounted. (Rotary feeders are generally divided into front mounted rotary feeders and side mounted rotary feeders)

Does the rotary feeder need to be equipped with an acceleration chamber and an exhaust chamber.

Do the inner chambers and blades of the rotary feeder require special treatment. (Does the inner cavity need to be wear-resistant? Choose V-shaped or P-type blades for the impeller. Generally speaking, P-type blades are straight and suitable for powder materials. Type blades are herringbone shaped, which effectively reduces material jamming between the rotor and the casing for granular material transportation.)

One of the measures

Whether the specifications of the reducer motor are explosion-proof (indicate the explosion-proof level).

As a type of unloading sensing machinery, the rotary feeder actually has a complex design structure, but it is relatively easy to operate. The star shaped unloader has its own unique design method, which completes the unloading and feeding work by rotating the impeller. In addition, the star shaped unloader is divided into single-layer, double-layer, and three-layer types according to the design structure. The unloader is an important equipment for storing, feeding, quantitatively feeding, airflow conveying, and dust removal equipment systems. The outlets of bag filters and cyclone dust collectors are equipped with star shaped unloaders to timely discharge dust from the dust hopper of the dust collector while ensuring the airtightness of the dust removal system.

If the rotating feeder is not maintained during use, it is inevitable that various problems may occur. Of course, in order to improve our work efficiency, we also need to learn to self check when the star shaped unloader malfunctions. Any equipment should be regularly inspected during use to prevent safety accidents caused by equipment wear and tear, which may delay production. Star shaped unloaders, as ash discharge systems for warehouses, silos, dust collectors, cyclone tubes, and screw conveyors, are also not included. Star shaped unloaders are generally used for discharging dust and small particles. After continuous improvement in recent years, the applicability of unloaders has become more extensive. They are specially designed to prevent jamming for large particles such as sawdust, wear and tear for hard materials such as stones, corrosion resistance for highly corrosive materials, and pneumatic conveying star shaped unloaders for working conditions with high pressure. The working principle of the star shaped unloader is that the motor rotating device drives the star shaped impeller to push the material out. In order to achieve the goal of no dust leakage in the star shaped unloader, rubber strips are embedded on the outer edge of the blades to strengthen the seal between the impeller and the shell. Since the unloader is such an important component, maintenance work must not be careless. If you have any questions or would like to know more about rotary feeders or other pneumatic conveying equipment, please feel free to call us for consultation.